The Briggs and Stratton Intek Repair Manual PDF provides comprehensive guidance for maintaining and repairing Intek engines, offering detailed instructions, troubleshooting tips, and model-specific repair solutions.

Overview of Briggs and Stratton Engines

Briggs and Stratton engines are renowned for their durability and reliability, powering various equipment like lawn mowers, generators, and pressure washers. The Intek series, a popular lineup, offers overhead valve (OHV) technology for enhanced performance and fuel efficiency. These engines are designed to withstand heavy use and require regular maintenance to ensure optimal functionality. With a wide range of models, Briggs and Stratton engines cater to diverse needs, from residential to commercial applications. Their reputation for quality has made them a preferred choice for outdoor power equipment worldwide.

Importance of Repair Manuals for Intek Engines

Repair manuals for Intek engines are essential for effective troubleshooting, maintenance, and repair. They provide detailed instructions, diagrams, and specifications tailored to specific models, ensuring accurate diagnoses and fixes. These manuals empower users to address common issues independently, saving time and money. By following the guidelines, users can maintain engine performance, prevent premature wear, and ensure safety. The manuals are indispensable for both DIY enthusiasts and professionals, offering a comprehensive resource to keep Intek engines running efficiently and reliably over their lifespan.

Why Use the Briggs and Stratton Intek Repair Manual PDF?

The Briggs and Stratton Intek Repair Manual PDF offers precise, model-specific guidance, ensuring accurate repairs and maintenance. It provides detailed diagrams, troubleshooting tips, and step-by-step instructions tailored to Intek engines. By using this manual, users can diagnose issues efficiently, avoid costly mistakes, and extend the engine’s lifespan. Its comprehensive coverage, including official specifications and genuine parts recommendations, makes it an invaluable resource for both professionals and DIY enthusiasts seeking reliable and effective engine care.

Downloading and Accessing the Briggs and Stratton Intek Repair Manual

The Briggs and Stratton Intek Repair Manual PDF is easily accessible online through official sources, providing comprehensive instructions and troubleshooting guides for optimal engine maintenance.

Steps to Locate Your Engine Model Number

To identify your Briggs and Stratton Intek engine model number, inspect the engine label or sticker, typically found near the engine or on the equipment it powers. The model number is usually a combination of letters and numbers, formatted according to Briggs and Stratton standards. Once located, use this number to search for the corresponding repair manual PDF online, ensuring compatibility and accuracy for your specific engine. This step is crucial for accessing the correct repair guide tailored to your engine’s specifications.

How to Download the Repair Manual from Official Sources

To download the Briggs and Stratton Intek repair manual PDF, visit the official Briggs and Stratton website or authorized platforms like ManualsLib or ManyManuals. Use the search tool to locate your engine model number and select the corresponding manual. Ensure the source is verified for authenticity to avoid counterfeit or incomplete guides. Follow the on-screen instructions to download the PDF, which typically requires a model number and may involve creating an account or completing a quick verification process. This ensures you obtain a genuine, model-specific repair manual tailored to your engine’s needs.

Verifying the Authenticity of the Repair Manual PDF

To ensure the Briggs and Stratton Intek repair manual PDF is authentic, download it from the official Briggs and Stratton website or trusted sources like ManualsLib. Look for the Briggs and Stratton logo, copyright information, and detailed technical content. Cross-reference the table of contents and part numbers with official specifications. Avoid third-party sites unless verified, as counterfeit manuals may lack critical information or contain errors. Always verify the source and content to guarantee the manual’s accuracy and reliability for your Intek engine repairs.

Maintenance and Repair Procedures

The manual provides detailed maintenance schedules, troubleshooting guides, and repair steps for Intek engines, ensuring optimal performance and longevity with proper care and timely fixes.

Routine Maintenance Practices for Intek Engines

Regular maintenance is crucial for extending the life of Intek engines. Key practices include oil changes, air filter cleaning, and spark plug inspections. Ensure proper fuel storage and use Briggs & Stratton Gasoline Additive to prevent degradation. Check and replace worn parts promptly, such as belts and blades. Follow the recommended maintenance schedule in the manual for model-specific guidance. Proper tool usage and adherence to safety protocols are essential for effective upkeep. Always refer to the official repair manual for detailed procedures and specifications to maintain optimal engine performance and reliability.

Common Issues and Troubleshooting Tips

Intek engines often face issues like hard starting, rough running, or low power output. Troubleshooting typically involves checking air filters, fuel systems, and spark plugs. Clean or replace these components as needed. Faulty carburetors or ignition systems may require adjustment or replacement. Refer to the repair manual for diagnostic procedures and model-specific solutions. Addressing these problems early prevents further damage and ensures optimal engine performance. Always follow safety guidelines and use genuine Briggs & Stratton parts for reliable repairs.

Advanced Repair Techniques for Intek Engines

Advanced repair techniques for Intek engines involve detailed diagnostic procedures and specialized tools. Rebuilding the engine, replacing internal components, or performing cylinder head overhauls are common advanced tasks. These repairs require a deep understanding of engine mechanics and adherence to torque specifications. Diagnostic tools like compression testers and leak-down kits help identify internal issues. Always follow the repair manual’s guidelines for disassembly and reassembly. Proper alignment and lubrication of moving parts are critical for restoring engine performance. Use genuine Briggs & Stratton parts to ensure durability and reliability.

Understanding the Repair Manual Structure

The Briggs and Stratton Intek Repair Manual PDF is structured with a detailed table of contents, technical diagrams, and a comprehensive parts list, ensuring efficient navigation and repair.

Navigating the Table of Contents

The table of contents in the Briggs and Stratton Intek Repair Manual PDF is organized to help users quickly locate specific sections, such as engine models, repair procedures, and troubleshooting guides. It typically includes chapters dedicated to routine maintenance, advanced repair techniques, and model-specific instructions. Users can easily navigate through diagnostic charts, maintenance schedules, and parts lists. The structured format ensures that even complex tasks are broken down into manageable steps, making it easier for both DIY enthusiasts and professionals to find the information they need efficiently.

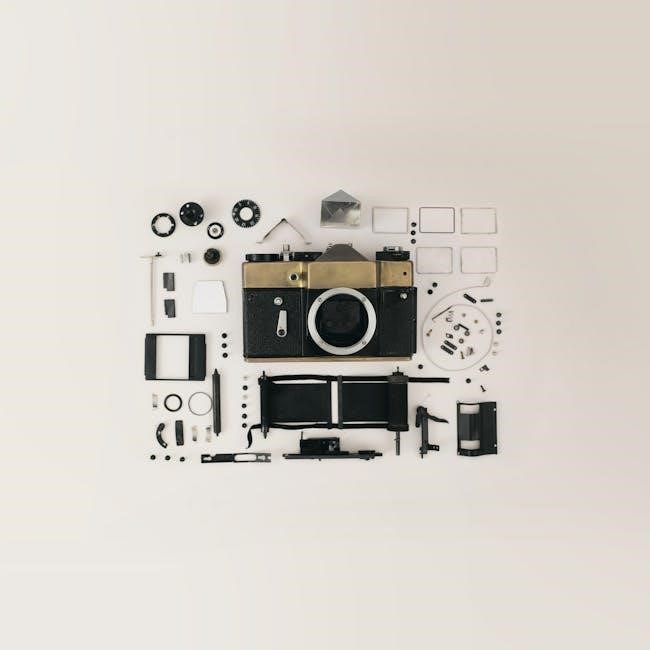

Interpreting Technical Diagrams and Illustrations

The Briggs and Stratton Intek Repair Manual PDF includes detailed technical diagrams and illustrations to guide users through complex repair procedures. These visuals clearly depict engine components, wiring diagrams, and step-by-step instructions for disassembly and reassembly. Color-coded labels and numbered sequences help users identify parts and understand their relationships. The diagrams are essential for diagnosing issues and ensuring repairs are performed accurately. They cater to both professionals and DIY enthusiasts, providing a clear visual reference for troubleshooting and maintenance tasks, enhancing the overall effectiveness of the repair process.

Using the Parts List for Effective Repairs

The parts list in the Briggs and Stratton Intek Repair Manual PDF is a crucial resource for ensuring accurate and efficient repairs. It provides a detailed inventory of engine components, including part numbers, descriptions, and compatibility information. This section helps users identify the exact parts needed for their specific Intek engine model, avoiding mismatches. By referencing the parts list, users can order genuine Briggs and Stratton components, ensuring reliability and performance. It also serves as a quick reference for verifying part quantities and specifications before starting repairs, making the process more organized and effective.

Briggs and Stratton Intek Engine Models

Briggs and Stratton Intek engines include models like the Intek I/C 850 Series and Classic 450 Series, known for their durability and versatility in various applications.

Popular Intek Engine Models and Their Specifications

Briggs and Stratton offers several popular Intek engine models, including the Intek I/C 850 Series, Classic 450 Series, and Quantum 675 Series. These engines are renowned for their reliability and performance. The Intek I/C 850 Series features a twin-cylinder design, while the Classic 450 Series is a single-cylinder engine. The Quantum 675 Series is known for its fuel efficiency and durability. Each model is designed for specific applications, such as lawn mowers, generators, and pressure washers. The repair manual provides detailed specifications, ensuring proper maintenance and repair for optimal performance. Authentic manuals are essential for accurate model-specific guidance.

Differences Between Intek and Other Briggs and Stratton Engines

Intek engines differ from other Briggs and Stratton models like Quantum and Classic Series due to their advanced features and design. Intek engines feature overhead valve technology, which enhances efficiency and reduces noise. They are widely used in lawn mowers and generators, offering reliable performance. In contrast, Quantum engines focus on fuel efficiency, while Classic Series engines provide basic, cost-effective solutions. These distinctions make Intek engines a preferred choice for demanding applications, emphasizing the need for model-specific repair guidelines to ensure optimal functionality. Understanding these differences is crucial for proper maintenance and repair.

Model-Specific Repair Guidelines

Briggs and Stratton Intek repair manuals provide detailed, model-specific instructions to ensure accurate repairs. Each manual covers unique aspects of engine models, such as Intek 121600 and 110600, with tailored troubleshooting steps and maintenance schedules. By adhering to these guidelines, users can address issues specific to their engine type, enhancing performance and longevity. This personalized approach ensures that repairs are efficient and effective, minimizing the risk of further damage. Always consult the manual corresponding to your engine model for precise guidance.

Safety Precautions and Best Practices

Always wear protective gear, ensure a clean workspace, and follow fuel safety guidelines. Adhere to environmental regulations during repairs to prevent pollution and ensure eco-friendly practices.

Essential Safety Tips for Handling Small Engines

Always wear protective gear, including gloves and safety goggles, when working with small engines. Ensure the area is well-ventilated and free from flammable materials. Disconnect the spark plug wire before starting repairs to prevent accidental starts; Use proper tools to avoid damage to engine components. Follow fuel safety guidelines, such as using a clean, dry cloth to wipe spills. Regularly check for loose connections and worn parts. Keep the engine and surrounding area clean to prevent debris buildup. Adhere to all safety precautions outlined in the repair manual to ensure a safe working environment.

Proper Use of Tools and Equipment for Repairs

Use the correct tools and equipment for Intek engine repairs to ensure safety and prevent damage. Always employ wrenches, screwdrivers, and pliers suitable for small engines. Keep tools clean and well-maintained to avoid slipping or damaging engine parts. Use genuine Briggs and Stratton replacement parts for reliability. Refer to the repair manual for specific tool recommendations and torque specifications. Store tools in a dry, secure location to maintain their condition. Following these guidelines ensures efficient and safe repair processes, minimizing risks of accidents or engine malfunction.

Environmental Considerations for Repair and Maintenance

Adhering to environmental guidelines during Intek engine repairs is crucial for minimizing ecological impact. Always use genuine Briggs and Stratton parts to prevent oil leaks and contamination. Properly dispose of hazardous materials like used oil, filters, and cleaning rags. Utilize biodegradable cleaning products when possible. Recycle metal and plastic components to reduce waste. Following these practices ensures sustainable repair and maintenance processes, aligning with eco-friendly standards. Refer to the repair manual for specific environmental recommendations and procedures.

Additional Resources and Support

Briggs and Stratton offers official support through service centers, online forums, and detailed repair guides. Utilize genuine parts and tools for optimal results, ensuring environmental compliance.

Briggs and Stratton Official Support and Service Centers

Briggs and Stratton provides extensive support through authorized service centers worldwide. Locate your engine’s model number and visit their official website to find nearby dealers. These centers offer genuine parts, tools, and expert assistance. For convenience, use the “Locate Model Number” guide to ensure accurate service. Contacting official support ensures you receive reliable, warranty-compliant repairs. This resource is invaluable for troubleshooting and maintaining Intek engines, guaranteeing optimal performance and longevity. Always rely on authorized centers for authentic parts and professional guidance.

Online Communities and Forums for Repair Enthusiasts

Online forums and communities are invaluable resources for Briggs and Stratton Intek repair enthusiasts. Platforms like repair forums, social media groups, and specialized websites offer a space to share knowledge, ask questions, and access tips from experienced technicians. These communities often provide troubleshooting advice, model-specific guidance, and real-world repair experiences. Many forums also host interactive videos, diagrams, and downloadable resources. Engaging with these groups can help you stay updated on the latest repair techniques and best practices, ensuring your Intek engine runs at peak performance. Active participation can also connect you with experts and DIY enthusiasts worldwide.

Recommended Tools and Parts for Intek Engine Repairs

For effective Intek engine repairs, use genuine Briggs and Stratton parts and tools. Essential tools include a spark plug socket, feeler gauge, and torque wrench for precise adjustments. Recommended parts like air filters, oil filters, and spark plugs ensure optimal performance. Always refer to the parts list in your repair manual for compatibility. Additionally, stock up on maintenance items such as Briggs and Stratton Gasoline Additive and high-quality motor oil. Using the right tools and parts guarantees safety, efficiency, and longevity for your engine.

The Briggs and Stratton Intek Repair Manual PDF is an essential resource for engine maintenance and repair, offering comprehensive guidance to ensure optimal performance and longevity of your Intek engine.

Final Thoughts on Using the Repair Manual Effectively

The Briggs and Stratton Intek Repair Manual PDF is a valuable resource for engine maintenance and repair. It provides detailed instructions, troubleshooting tips, and part lists, ensuring effective fixes. By following the manual’s guidelines, users can optimize engine performance and longevity. Accessing the manual through official sources guarantees authenticity and reliability. Regular maintenance, as outlined, prevents issues and extends engine life. Always use genuine Briggs and Stratton parts for durability. Safe practices and adherence to the manual ensure successful repairs and equipment longevity.

Encouragement for Proper Maintenance and Repair Practices

Proper maintenance and repair practices are essential for extending the life of your Briggs and Stratton Intek engine. Regularly reviewing the repair manual ensures familiarity with essential procedures, helping you address issues promptly. Adhering to the manual’s guidelines prevents costly damage and enhances engine performance. By staying proactive with routine checks and using authentic parts, you maintain reliability and efficiency. Encourage others to adopt these practices to ensure their equipment runs smoothly for years to come.